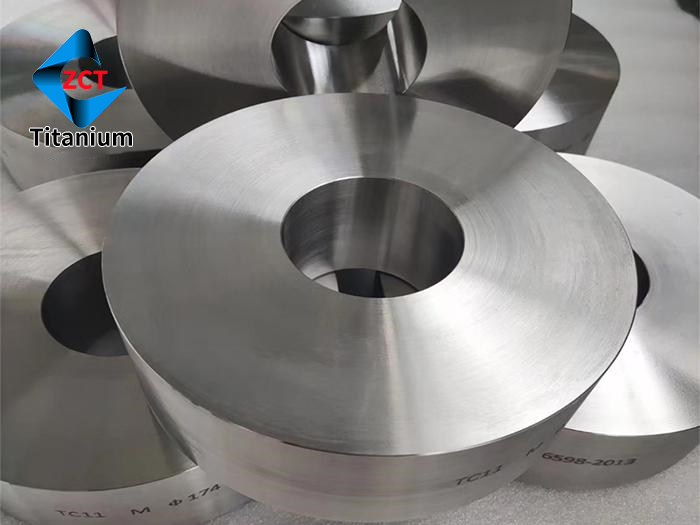

GR5 titanium ring

Forgeable piece refers to the workpiece or blank obtained by forging the metal blank.

The quality inspection items of forgings are as follows:

(1) Geometry and dimensions

The overall dimensions of general forgings shall be tested with steel ruler, caliper, sample plate and other measuring tools; Die forgings with complex shape can be accurately detected by scribing method.

(2) Surface quality

If there are cracks, crushing and folding defects on the surface of forgings, they can be generally found with the naked eye. Sometimes the crack is very small, and the fold is not clear, it can be observed after cleaning; If necessary, flaw detection method can be used for inspection.

(3) Internal organization

Whether there are cracks, inclusions, looseness and other defects in the forging, the macrostructure on the forging section can be checked with naked eyes or with 10-30 times magnifier. The commonly used method in production is acid etching inspection, that is, cut samples at the parts of forgings that need to be inspected, and use acid etching to clearly show the macro structure defects on the section, such as forging streamline distribution, cracks and inclusions.

(4) Metallographic examination

The distribution of carbide, grain size and decarburization depth can be checked by means of the inspection method of observing the fracture microstructure of forgings with metallographic microscope.

(5) Mechanical properties

Mechanical property inspection items mainly include hardness, tensile strength and impact toughness. Sometimes cold bending test and fatigue test can be conducted according to the design requirements of parts.

The above quality inspection items are sometimes used separately according to the design requirements and actual production conditions, sometimes one by one inspection is required, and sometimes sampling inspection is required for each batch of forgings. The qualification of forgings can be assessed through quality inspection. For the forgings with defects, the causes shall be analyzed and the measures to prevent defects shall be proposed.