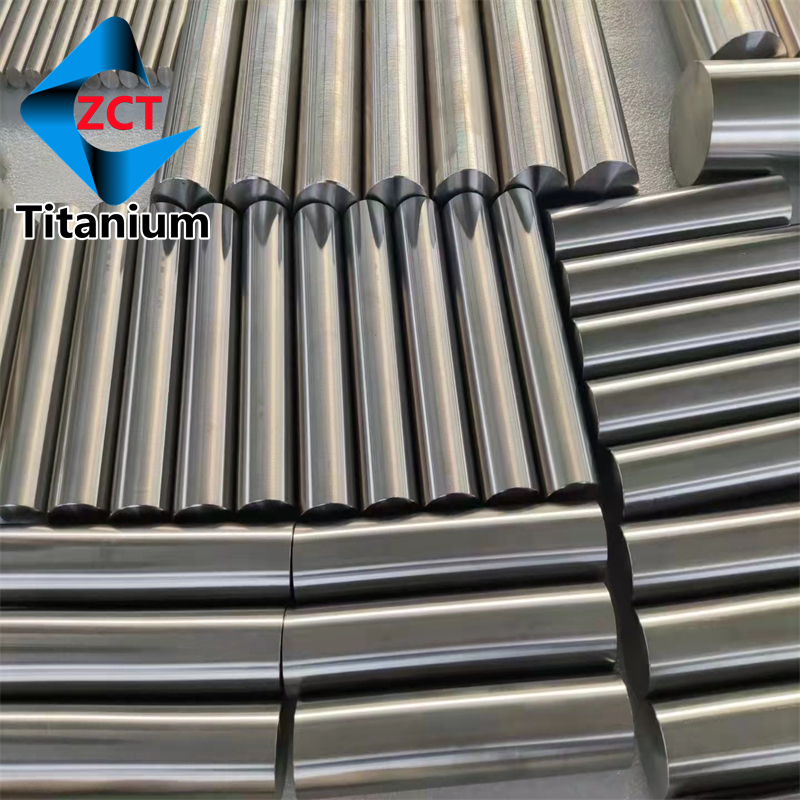

Titanium Bars(GR12)ASTM B348

TC4 titanium alloy rod, Ti6Al4V titanium rod, GR5 titanium rod and titanium alloy are widely used in industrial research and other fields. The rapid development of titanium alloy has been recognized by international industrial aerospace and other fields. In particular, TC4 titanium rod, TC4 titanium alloy rod, TC4 titanium forging has a strong market prospect. The special properties of Ti-6Al-4V titanium rod and GR5 titanium rod are:

(1) Ti6A14V belongs to α+β Type I alloy, large consumption

(2) It has good technological properties. Its conventional thermal deformation is carried out in the two-phase zone. The deformation must be greater than 50% to transform the coarse original Widmanstatten structure into equiaxed structure

(3) After deformation processing, according to different needs, stress relief annealing (600 ℃ heat preservation, air cooling), ordinary annealing (700-800 ℃ heat preservation, air cooling), recrystallization annealing (940 ℃ heat preservation, furnace cooling to 480 ℃ air cooling) and double annealing (940 ℃ heat preservation, air cooling+700 ℃ heat preservation, air cooling) can be used The microstructure obtained by stress relief annealing and ordinary annealing is non recrystallized or partially recrystallized, with high strength; Equiaxed after recrystallization annealing α+ Intergranular p structure, good plasticity; Equiaxed after double annealing α+β Structure, close to bimodal structure, with good comprehensive properties (about 900-1000MPa, δ 10%, ψ About 35% - 45%)

(4) The strength can be increased by 20% - 30% by strengthening heat treatment It is generally believed that primary growth can be obtained by aging at 850-950 ℃ α Appropriate amount of microstructure and better comprehensive dielectric properties The hardenability of TC4 alloy is poor, and the cross section of parts subject to enhanced heat treatment is generally not greater than 40 mm

(5) The alloy has good weldability, and the temperature in the weld zone is not lower than 90% of the matrix; The plasticity is similar to that of the slave metal

(6) Its corrosion resistance is close to that of pure titanium. It can work under 400 ℃ for a long time and 700-750 ℃ for a short time When the content of oxygen and nitrogen in the alloy is low, TC4ELI alloy can maintain good plasticity at - 196 ℃ and can be used to make low temperature and high pressure vessels

TC4 titanium alloy rod is also called GR5 titanium rod and Ti6Al4V titanium rod

TC4-Ti6Al4V-GR5 titanium alloy rod has a series of advantages, such as excellent corrosion resistance, small density, high specific strength, good toughness and weldability, and has been successfully applied in aerospace, petrochemical, shipbuilding, automobile, medicine and other departments

Specification of TC4 titanium alloy bar:

φ (3.0--350)mm × 50. Optional specifications, or customized zero cutting according to customer specifications, implementation of standards, and delivery on schedule

Application scope of TC4 titanium alloy bar:

Petroleum, chemical, aerospace, shipbuilding, medicine and other industries

Executive standard of TC4 titanium alloy bar:

Domestic: GB/T2965-2007, GB/T13810-2017

American standard: ASTM B348, ASTM F136, ASTM F67, AMS4928